Mexico City, Mexico - Founded in 2010 as part of the Litopolis Group, Flexopolis specializes in packaging solutions, with a focus on labels and shrink sleeves for the automotive, personal care, and food industries. After poor experiences with flexo technology in the past, the company decided to invest in the BOBST MASTER M5 label press. According to CEO Patrícia Ruiz (pictured above), they couldn’t be happier: “With the special features from BOBST, we can do coupon labels and we’re almost ready to start producing in-mold labels too. This is very interesting because Mexico is not yet as developed in this market.”

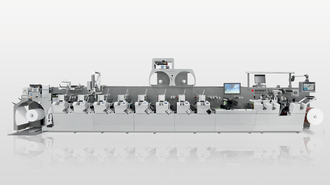

BOBST MASTER M5 hits the spot

The equipment’s ease of operation and the high print quality were the main differentiators that made the decision to invest with BOBST easy. This is the second MASTER M5 press acquired by Flexopolis, and its trust in BOBST is only growing stronger.

“We have very demanding customers, so the most important aspect for us is to deliver the best quality products, both in terms of register and color. We also need better finishes and products that other companies can’t offer,” stated Patrícia.

Reinforcing the importance of innovative and high-quality products in the Mexican market, she explained that being able to count on BOBST to produce these labels with greater agility and simplicity is, without a doubt, a very welcome addition to the portfolio.

The 430mm wide BOBST MASTER M5 is configured for 8-color UV flexo printing. Its PrintTutor system ensures precise and automatic register control, offering the ability to work with multiple substrates. The MASTER M5 can be equipped with different inline accessories, expanding the application range reachable by converters.

Praising reliability and productivity

Over the past 15 years, Flexopolis has multiplied its production capacity more than five-fold, delivering quality products to the Mexican market that are exported worldwide by its customers.

The advanced features of the MASTER M5 that provide faster, simpler job changes and more automated operation have already been praised by Flexopolis’ prepress operators and printers. They celebrate the ease of working with the machine and BOBST’s responsive support in resolving any printing issues.

“The biggest advantage of working with a company like BOBST is that they’re global and always at the forefront of new solutions. When we have questions, we can call them at any time, and they’re always ready to help,” explained Ruiz.

She was pleasantly surprised by the high reliability of the press and the dedication of the BOBST team right from the beginning of the negotiation process. Today, she praises the absence of maintenance downtime, and the new level of productivity achieved by the company: “Of all our machines, the BOBST MASTER M5 is the most productive by a significant margin, almost 30%. The simple truth is that it allows us to run very fast and deliver high-quality products.”

Today, Flexopolis has a much lower environmental impact thanks to the savings on substrate and ink waste during setup and printing, in addition to lower energy consumption and less waste at the end of the process. This has been made possible by the addition of the optional PrintTutor system which automatically controls and corrects registration using cameras that certify the longitudinal and transversal accuracy of the print.

Collaboration for a successful future

All these benefits have led Flexopolis to consider new investments with BOBST in the near future, as the company seeks to further raise the level of quality and productivity, crowning the decision to trust BOBST an undisputed success.

“We are delighted that Flexopolis has decided to put its trust in BOBST for a second time, and even more delighted to witness its fantastic success,” said Carlos Rodriguez, BOBST Sales Manager Narrow Mid Web. “Flexopolis is an innovation leader in the Mexican market, and we look forward to continuing our collaboration, together pushing into new exciting label segments.”

Reliable Tamper Evidence for Pharma Pack...

Schreiner MediPharm offers a novel cut-through indicator for closure seals that makes tampering attempts clearly visible; solution prevents tampering with folding boxes by cutting open seals and reapplying them with transparent adhesive tape.

Scodix Flex Financing Throughout Europe

Previously limited to Germany, OEM strengthens partnership with PEAC Solutions to power expanded Machine as a Service (MaaS) offering; three different options are available.

Window Graphics for Canadian University

North American PSP heads "back to school" with Drytac ViziPrint Impress Clear PET film for interior ...

Monadnock's Newest Fine Papers

Monadnock Paper Mills, Inc. unveils latest swatchbook of FSC-certified paper for graphic designers, ...

Print Fun, (Not News) . . .

FREE DOWNLOAD: 2025 Color-Logic calendar showcases stunning embellishments!

Powering Up Postpress

NEW FINISHING EQUIPMENT: Complete Design & Packaging (North Carolina, USA) foresees doubling its capacity in the gluing department, increasi...

Next-gen Semiconductor Packaging

As part of the US-JOINT Consortium, TOPPAN is collaborating with American and Japanese material and equipment manufacturers in Silicon Valle...

Supporting Stricter 2D Code Requirements

With GS1 Sunrise 2027 on the horizon, Domino prepares to assist customers in regulated Industries, including those in the pharmaceutical and...

Latest News

Subscribe

Subscribe to our INKISH newsletter

Subscribe to our newsletter

South Africa's 1st RHINO E Flatbed Finis...

NEW EQUIPMENT INSTALLED: SA Litho partners with Pantec and ROTOCON. The RHINO finishing device features speeds of up to 18,000 strokes per hour, enabling rapid and efficient production of premium labels while maintaining the precision required for in...

Image360 Scores Big!

U.S. sign-printing franchise again sponsorship the upcoming "Go Bowling Military Bowl" American college football game.

Starting the Newspaper Press!

National nonprofit organization for local news fires up printing press operations in Denver, Colorado; National Trust for Local News is estimated to save local, U.S. publishers at least $500,000 (USD) in 2025.

AlphaGraphics Extends Trade Assn. Member...

Leading nationwide brand renews PRINTING United Alliance membership for five years in North America;...

SG360° Using Sentinel Auto Ink Dispenser...

Since 2007, U.S. PSP manages printing of colorful direct mail with iPro automated ink dispensing car...

Sustainable Adhesive Tape Usage

Afera, the European adhesive tape association, has released new guidance on the sustainable use of a...

Grandma's Jammin' with ColorWorks!

Grandma's Jam House installs ColorWorks solutions for enhanced precision and customization in produc...

Lecta Reducing Emissions

nyloflex XSN Launched for Narrow Web

NEW PRODUCT: XSYS launches new flexo plate innovation for superior performance and flexibility in narrow-web printing; flat-top dot structu...

Epson's Responsible Business Practices

Two factories -- one in the Philippines and one in Malaysia -- have achieved Platinum Recognition under the Responsible Business Alliance's ...

Introducing Vantage v 4.0

PRODUCT NEWS: New software version enhances efficiency for print and signage installations; developer has UK and US presence.

Printing Press Catches Fire

Employees of Dingley Press (Maine, USA) were evacuated from the production facility after a printing press caught on on fire December 9; thankfully, no injuries were reported.

Login

New User? Signup

Reset Password

Signup

Existing User? Login here

Login here

Reset Password

Please enter your registered email address. You will recieve a link to reset your password via email.

New User? Signup