From October 18-22 Horizon International hosted the Horizon Smart Factory 2021 event in collaboration with Canon, Fujifilm, Konica Minolta, Miyakoshi, Ricoh, Riso, Ryobi, and Screen to showcase the latest in labor saving, automated finishing solutions. While COVID-19 related travel restrictions limited in-person attendance to domestic customers, sign-ups for the online sessions surpassed six thousand registrants.

This year’s theme was “Connectable Factory Automation” and the exhibited solutions delivered on that promise with several inline press and finishing device configurations—many shown for the first time.

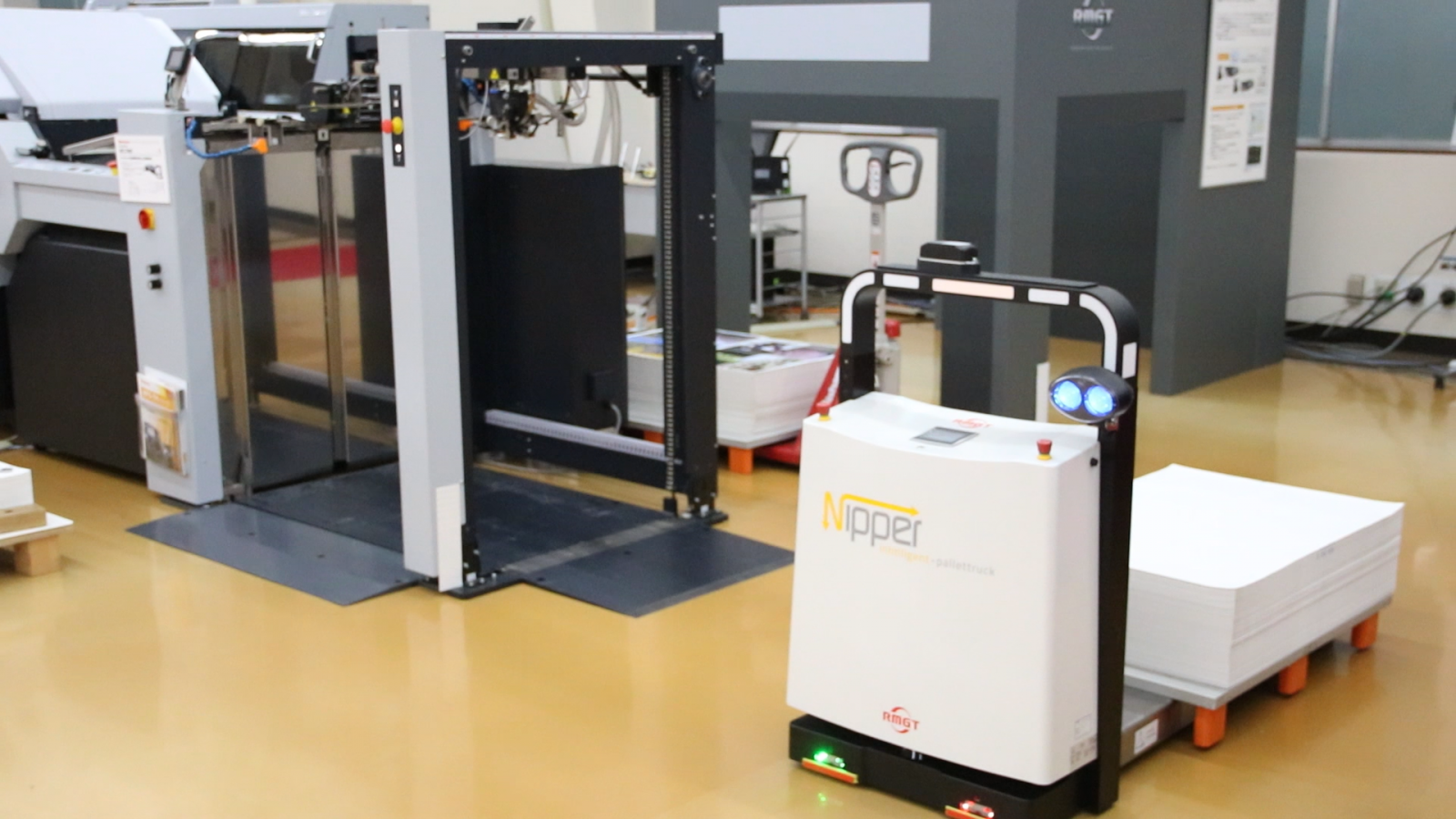

Why have your skilled employees performing repetitive, labor intensive work when their time can be better spent elsewhere? Horizon showed how robots can be used for feeding book blocks into binders, palletizing folded signatures, and even offloading die-cut and stacked pieces for banding.

Inline solutions skip the transport step in usual workflows and streamline production. At HSF2021, Horizon showed inline book production with digital presses (web and cut sheet) and printed roll-to-book solutions. Two cut sheet presses ran inline with the 4-clamp perfect binder BQ-500 to print both the book block and cover sheet for true zero-makeready book-of-one production.

No one is perfect and mistakes happen, but what happens if we take the human element out of the equation? Inline cut sheet processing solutions with the Horizon SmartSlitter and rotary die-cutter RD-N4055 demonstrated how we can avoid mistakes at the guillotine cutter by leveraging the automated technology for perfect output every time.

The entire exhibition floor was connected to Horizon’s cloud-based iCELiNK network. iCELiNK allows users to monitor machine status, track jobs in the bindery, analyze operator and system performance, and more.

Automated, inline solutions don’t need to be large, costly investments. Horizon showed how even a one-clamp perfect binder can be integrated into a smart binding system to reduce touchpoints, increase productivity, and lower labor costs.

For those unable to attend the live sessions, recordings are now available for viewing on the official event website.

https://www.horizon.co.jp/ja/exhibition/hsf_2021_en/hsf_2021_02.html

Tue November 19th

Count down to november ...

Our new NEWS is soon ready to be published!

Count down to news

On November 25th our new NEWS solution goes online - we are looking forward to share with you!

Tue October 15th

• vigc “ het congres “ ...

VIGC celebrates 25 years of passion and innovation in the Benelux graphic sector.

Fri October 11th

Pack-smart inc. to show...

Pack-Smart will showcase its Delta-X Track and Trace solutions at Pack Expo International 2024 on Booth #W-16075

Emt international welco...

Pecoraro resides in Minnesota and is covering the upper Midwest, West, and Southwest areas of the United States.

Thu September 19th

Hiflow solutions unveil...

HiFlow demonstrates its new tools for label converters and flexo companies

Wed September 18th

Ultimate tech unveils g...

September 4, 2024 – Ultimate Tech announced collaboration with GMG Color

Sun September 15th

Global graphics softwar...

Global Graphics Software and Mark Andy extend partnership to integrate SmartDFE into Digital Series HD press

Thu September 12th

Global graphics softwar...

Global Graphics Software and Dantex announce partnership to integrate SmartDFE into Pico range of UV digital presses

Tue September 10th

New printvis release: e...

New release out this week

Subscribe

Subscribe to our INKISH newsletter

Login

New User? Signup

Reset Password

Signup

Existing User? Login here

Login here

Reset Password

Please enter your registered email address. You will recieve a link to reset your password via email.

New User? Signup