By Editor Morten B. Reitoft

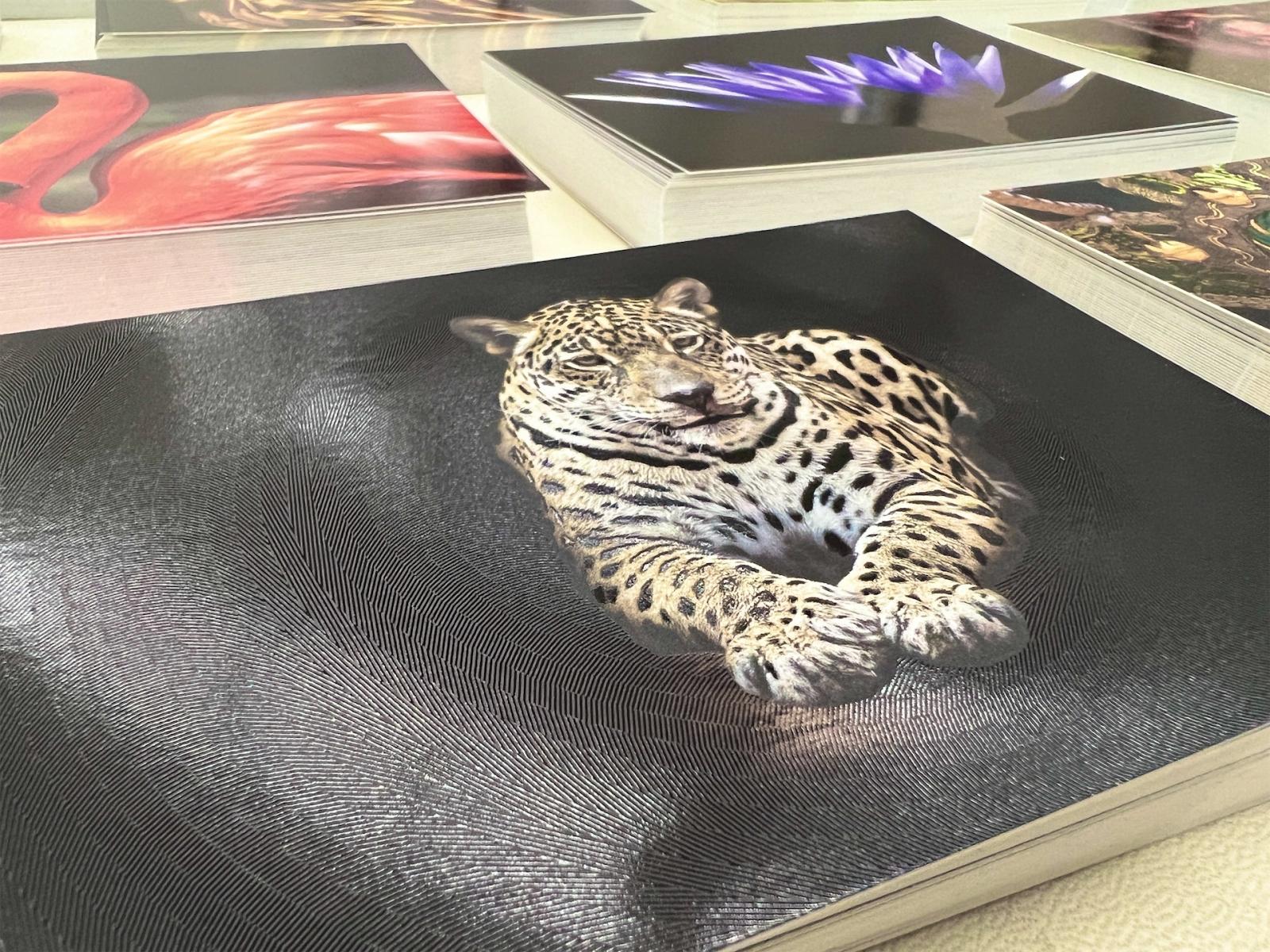

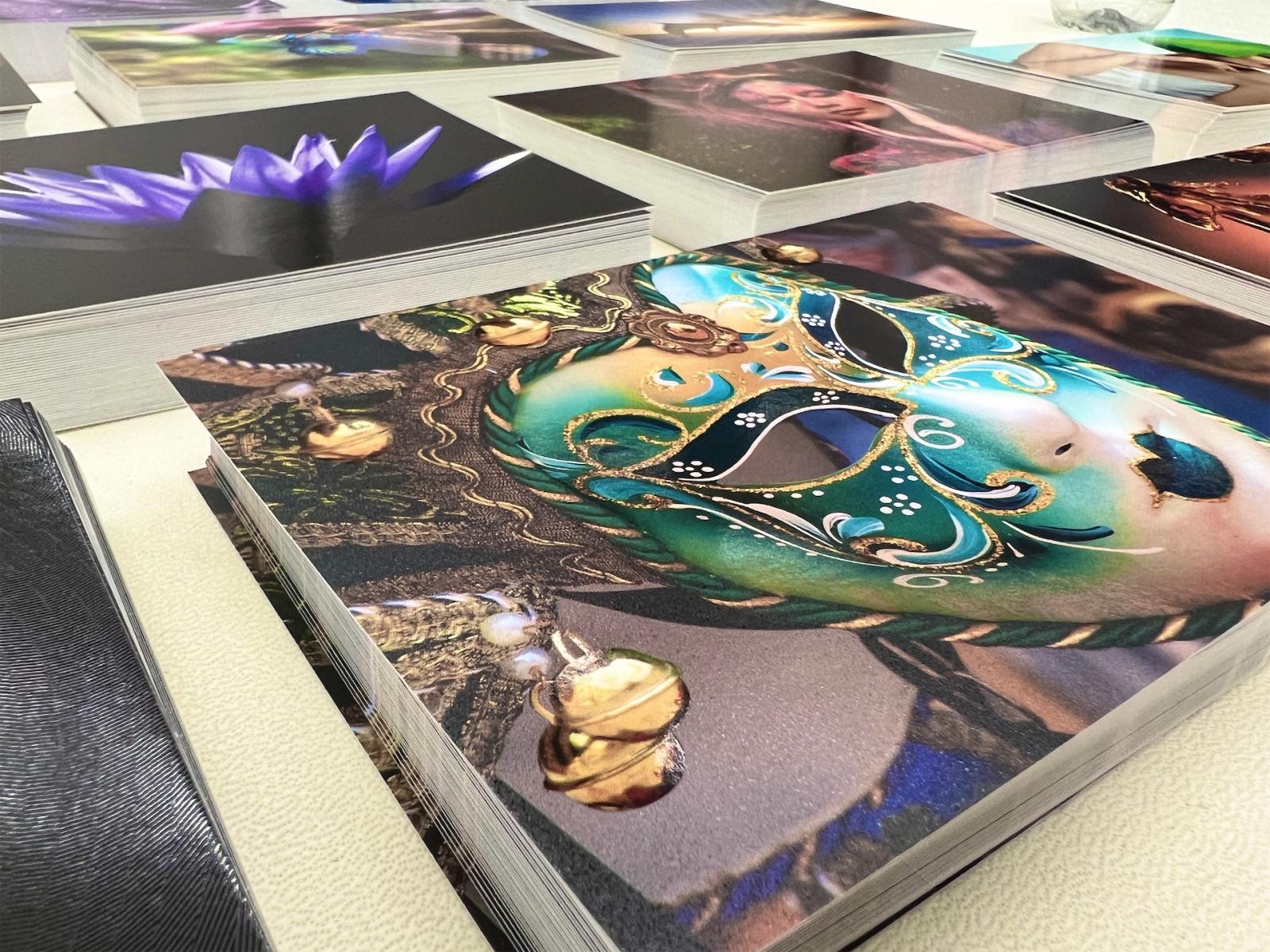

This is our first visit to Komori's European headquarter; that's a fantastic building with a great experience center - and today, the frame for a Komori Open House event. A little less than 200 people are attending today. You will hear Turkish, Italian, English, Dutch, German, and many more languages spoken in a lively environment with a mixture of partners/exhibitors and presentations of Komori presses. The show's star is the G37 platform configured in an 8-color perfection setup with PDF/Auto Pilot functionality. The latter means that the machine is set up entirely autonomously and checks plates and output against the PDF with its camera inspection system.

MBO, which was acquired by Komori some years ago, presents its successful Cobo Stack along with MBO folders. The robots on the Cobo Stack increase the productivity in the bindery, and several hundred are in the field now, serving customers daily.

The Open House opened at 9:00 and started with a short presentation by Eiji Kajita, who works for Komori International Europe as Head of Operations and President. He starts directly with an analysis describing the focus on resources, waste, energy, inflation, and market development as challenges that need to be addressed. Komori addresses the challenges with new technology that, according to Mr. Kajita, saves energy, reduces waste, and brings up the OEE/Productivity, essentially offering customers more for less. The G37 platform is an SRA-1 platform, enabling 16 A4 pages production, with less waste than B1, as the B1 format will require larger plates, blankets, etc. I do, however, believe that most printers - even with a B1 machine will consider using smaller plates, smaller blankets, and smaller format papers - but of course, why then buy a larger format printer?After the presentation, the G378P is presented with three jobs on the same paper, different print runs, and using Komori's Auto Pilot solution that enables the setup of jobs without any operators, who now only need to place and remove plates physically.

As mentioned, the Open House is well-visited and offers a lot of knowledge and information. Great opportunity to learn!

Thu June 27th

Hiflow solutions offers...

Windows-based app gives users an easy-to-use imposition solution to replace costly and error-prone manual imposition processes.

Wed June 26th

Top 8 mind blowing prin...

While printing may appear to be a simple process, there are some interesting facts about this art form that you may not be aware of.

A comprehensive guide t...

As the world of e-commerce continues to expand, Shopify has emerged as a leading platform for businesses looking to establish a strong onlin

Tue June 25th

Factor druk bombed by r...

The story must be told, and we have decided to send Editor-in-Chief, Morten B. Reitoft to Kharkiv

Sun June 23rd

Respect for innovation ...

The small Danish company OnPrint has developed a sustainable alternative to a Roll-Up - now Patent Pending

Fri June 7th

Designnbuy releases des...

Dallas, Texas – DesignNBuy, a leading provider of web to print solutions, announced the launch of DesignO 2.0, a revolutionary web to print...

Wausau container corpor...

Paperboard manufacturer positions itself for the future by embracing an automated Industry 4.0 solution.

Thu May 30th

Spencermetrics showcasi...

SpencerMetrics will be present at 3 booths during Drupa 2024 - Horizon, HP, and EMT

Designnbuy releases des...

Dallas, Texas – DesignNBuy, a leading provider of web to print solutions, announced the launch of DesignO 2.0, a revolutionary web to print...

5 reasons why printing ...

Dallas, Texas – DesignNBuy, a leading provider of web to print solutions, announced the launch of DesignO 2.0, a revolutionary web to print...

Subscribe

Subscribe to our INKISH newsletter

Login

New User? Signup

Reset Password

Signup

Existing User? Login here

Login here

Reset Password

Please enter your registered email address. You will recieve a link to reset your password via email.

New User? Signup